SAKE BREWING PROCESS

Sake is a fermented alcohol, like beer or wine, but with a more complex fermentation process.

Difference in fermentation process

Whiskey and brandy are distilled types of alcohol. Japanese Sake, like beer and wine, is a fermented alcohol and although they share this in common, the fermentation process is quite different. Perhaps it is this difference that gives Sake its unique flavor and the mystery surrounding Japanese Sake. See below for more information.

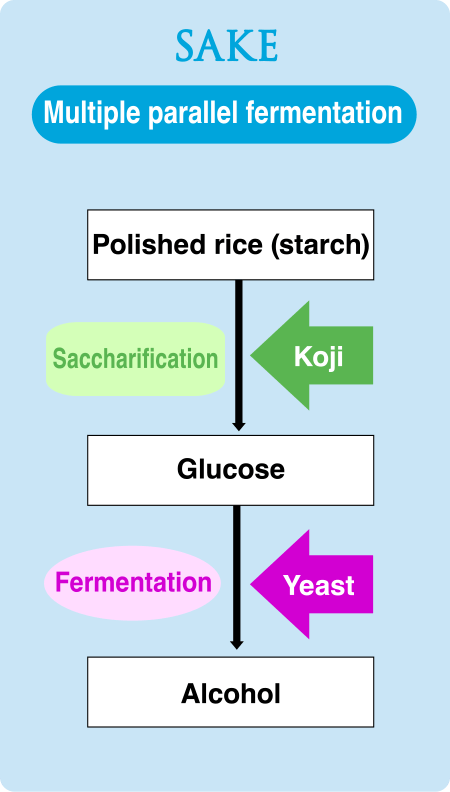

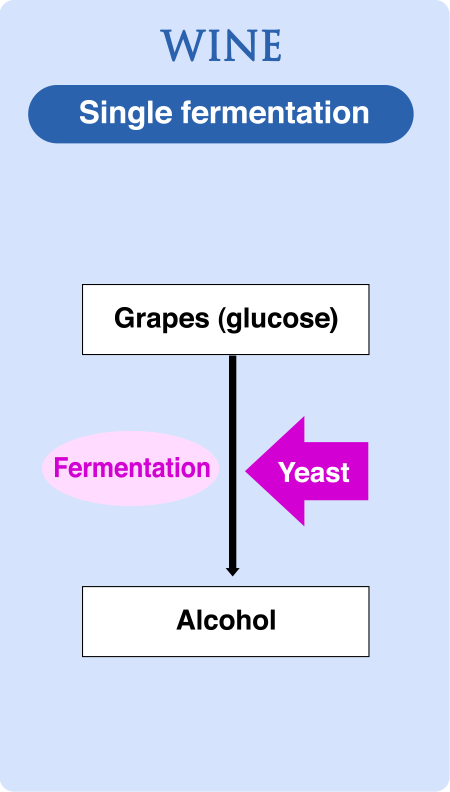

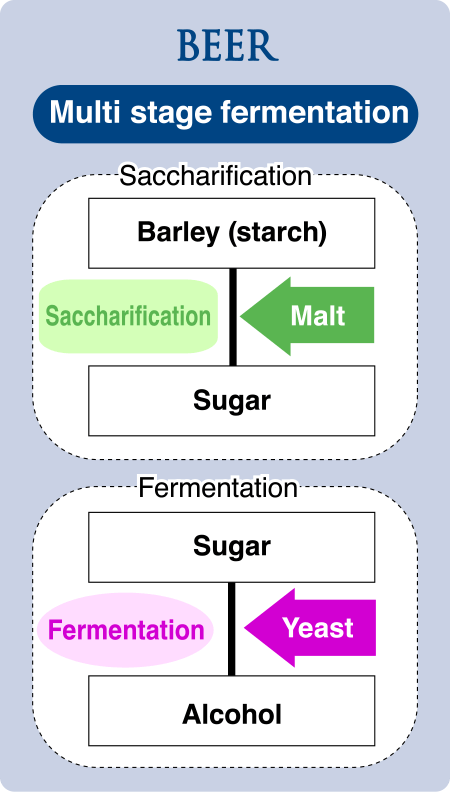

Brewed beverages include sake, wine, beer, etc. However, the fermentation process varies greatly among.

In particular, the two-stage conversion, in which (1) the koji enzymes convert the starch in the rice into glucose (saccharification) and (2) the yeast converts the created glucose into alcohol (fermentation) occurs simultaneously in the same moromi tank.

This process under which saccharification and fermentation occur at the same time and in the same tank is called multiple parallel fermentation and this is relatively unique to Japanese sake.

Wine, another brewed beverage is brewed from grapes, which are full of sugar therefore does not require such as complex process.

Beer, like Japanese sake is brewed following saccharification and fermentation processes. However, this this processes occur separately and are not simultaneous.

JAPANESE SAKE BREWING PROCESS

-

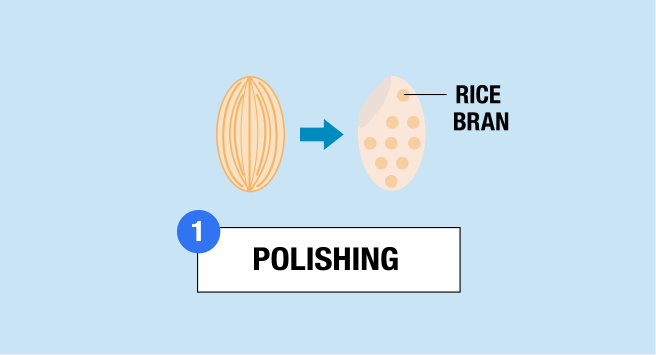

(1)Polishing rice for brewing

Sake Rice is grown especially for brewing. The grains are larger and low protein content.The rice is carefully polished in a specially designed milling machine.

-

(2)Washing

After polishing, the rice is washed to remove powder particles.

-

(3)Soaking

The rice is soaked in water to increase moisture content.

-

(4)Steaming

The rice is steamed for 40-60 minutes. After steaming, the rice is cooled to be used in either main fermentation process or koji making process.

-

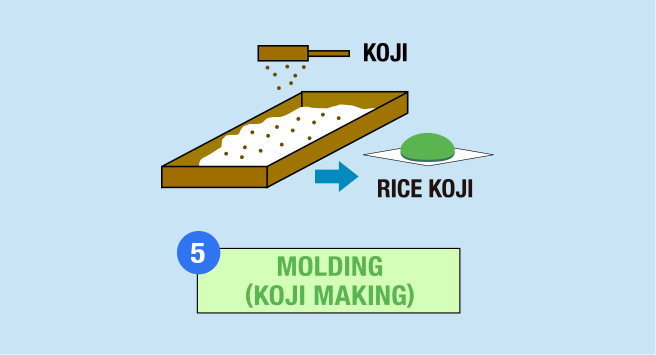

(5)Koji making

Koji is an important element and largely affects sake quality.

The koji is cultivated while carefully monitoring heat and humidity. -

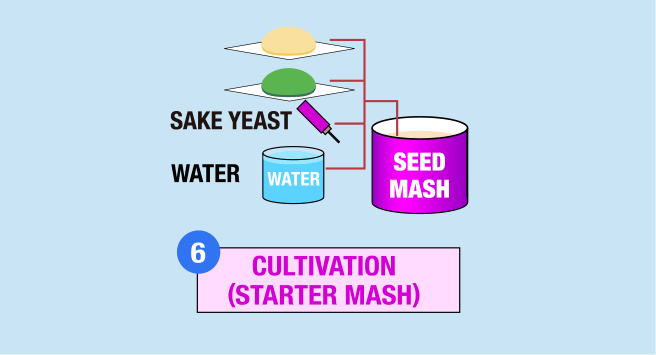

(6)Starter mash

Steamed rice, water, yeast, and koji are combined in a small tank to create the starter mash. This technique was developed back in the Edo period.

-

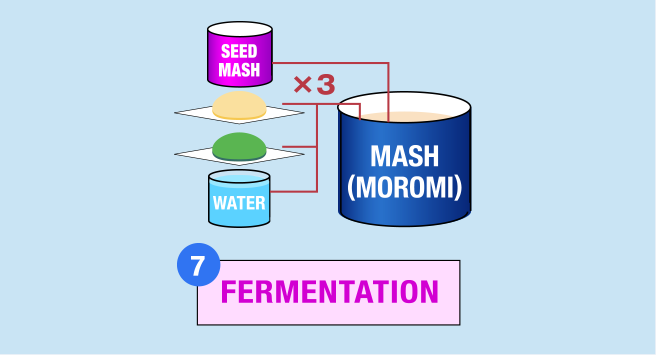

(7)Fermentation

Koji, more steamed rice and water are added to the starter mash to accelerate yeast fermentation. This is done over three successive stages.

-

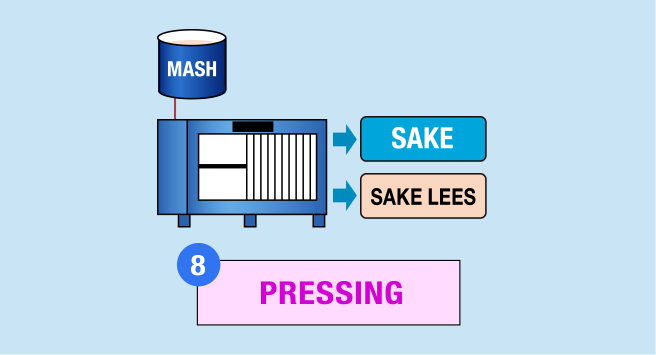

(8)Pressing

After 20-30 days of fermentation, the mash is passed through a press separating the sake from the lees.

-

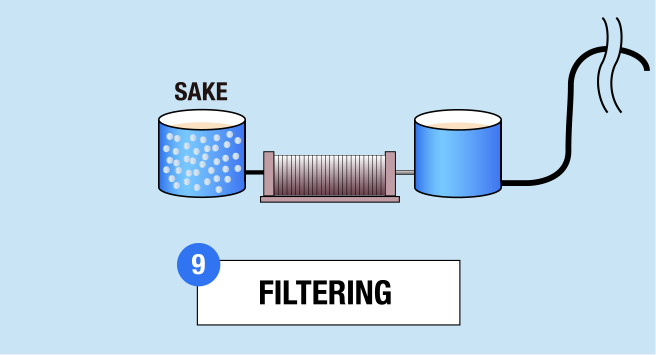

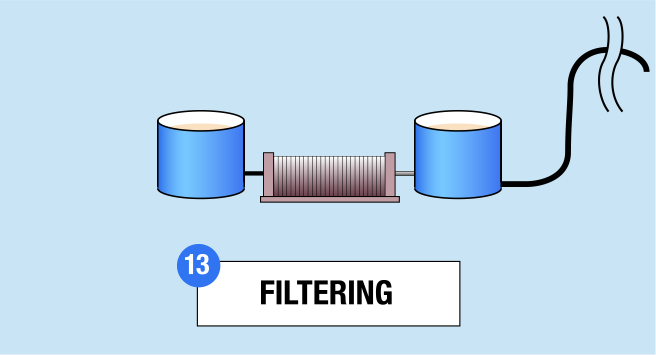

(9)Filtering

The sake is filtered to remove unwanted flavor and very fine impurities.

-

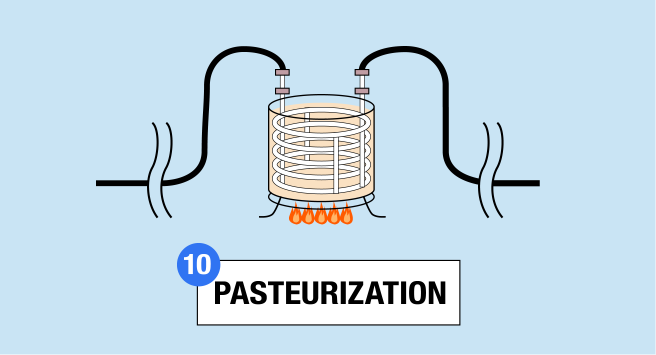

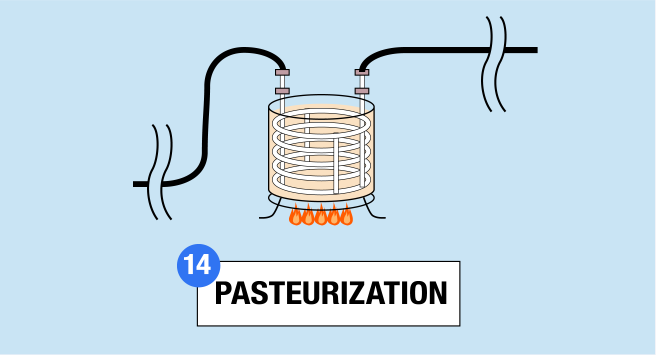

(10)Pasteurization

Sake is generally pasteurized under low temperature 60-65 degrees to kill off bacteria after it is filtered and again after the maturation period.

-

(11)Maturation

The sake is stored about 6 months to mature in a tank.

-

(12)Adding water

After Maturation, sake is diluted with water to adjust the alcohol content.

-

-

-

-

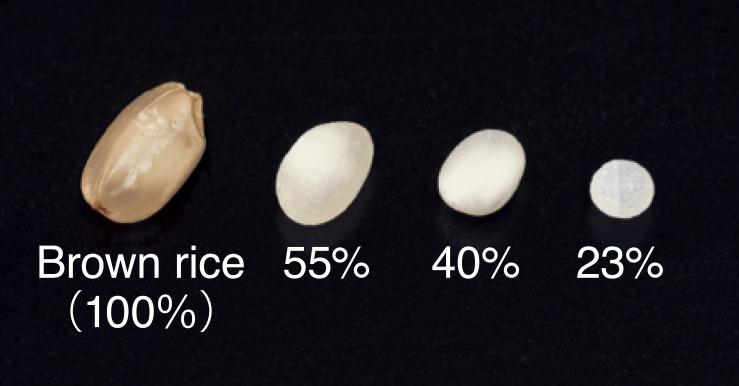

Rice polishing rate in specific classes of Japanese sake

In the sake brewing process, the exterior shell of the rice is removed and only the kernel, better suited to the brewing process, is used. The rice polishing rate is an indication of how much of the original grain has been removed. For example, a polishing rate of 60% indicates that 40% has been removed and only the remaining 60% is used in the brewing process.

Sake with a polishing rate of 50% or less is known as Daiginjo-shu and Junmai Daiginjo-shu, 60% or less is called Ginjo-shu and Junmai Ginjo-shu and 70% or less Honjozo-shu and Junmai-shu. The more the rice is polished the stronger the aroma and more delicate the flavor. Generally sake with a low polishing rate is more expensive.

-

■Ginjo-shu

- 【Ingredients】

- Rice, koji, brewer’s alcohol

- 【Rice polishing ratio】

- 60% or less

- 【Ratio of koji to the amount of rice】

- 15% or more

- 【Aroma/flavor characteristics】

- Precise, labor intensive brewing process, unique aroma/flavor and good color

-

■Daiginjo-shu

- 【Ingredients】

- Rice, koji, brewer’s alcohol

- 【Rice polishing ratio】

- 50% or less

- 【Ratio of koji to the amount of rice】

- 15% or more

- 【Aroma/flavor characteristics】

- Precise, labor intensive brewing process, unique aroma/flavor and very good color

-

■Junmai-shu

- 【Ingredients】

- Rice, koji

- 【Rice polishing ratio】

- -------

- 【Ratio of koji to the amount of rice】

- 15% or more

- 【Aroma/flavor characteristics】

- Good aroma/flavor and color

-

■Junmai Ginjo-shu

- 【Ingredients】

- Rice, koji

- 【Rice polishing ratio】

- 60% or less

- 【Ratio of koji to the amount of rice】

- 15% or more

- 【Aroma/flavor characteristics】

- Precise, labor intensive brewing process, unique aroma/flavor and good color

-

■Junmai Daiginjo-shu

- 【Ingredients】

- Rice, koji

- 【Rice polishing ratio】

- 50% or less

- 【Ratio of koji to the amount of rice】

- 15% or more

- 【Aroma/flavor characteristics】

- Precise, labor intensive brewing process, unique aroma/flavor and very good color

-

■Honjozo-shu

- 【Ingredients】

- Rice, koji, brewer’s alcohol

- 【Rice polishing ratio】

- 70% or less

- 【Ratio of koji to the amount of rice】

- 15% or more

- 【Aroma/flavor characteristics】

- Good aroma/flavor and color

Japanese Sake Glossary

Sake Meter Value (SMV)

SMV is a general guideline to the sweetness or dryness of the sake. It is a measure of the specific gravity of the ingredients of the sake, incuding sugar and amino acids, and the alcohol content relative to the water content. The sweetness found in sake is derived from sugar so the higher the sugar content, the higher the specific gravity, lowering the sake meter value. On the other hand, the higher the alcohol content, the lower the specific gravity will be, increasing the sake meter value.

Sweet sake will have a SMW in the negative figure range while dry sake will have a SMV in the positive figure range.

Amino Acid Level

Amino acid level refers to the amount of amino acids, such as glutamic acid, found in sake and has an effect on the crispness of the flavor and how easily it matures. The amino acid level is an important element which determines the sweetness, richness, acidity and bitterness of Japanese sake. In general, high levels indicate a more full-bodied, richer flavor, while low levels indicate a lighter, cleaner taste. High levels of amino acid also mean the sake will mature easily.

Sake Rice

This is also known as “Sakamai” or brewer’s rice. In comparison to normal table rice, sake rice has higher starch content, lower protein and fat content. And also it is more absorbent. Leading varieties of brewer’s rice include Gohyaku-man-goku, Yamada Nishiki and Omachi. Gohyaku-man-goku is the most commonly used and was developed in Niigata Prefecture. Gohyaku-man-goku is a descendant of a variety of rice called "Kikusui".

Koji

Koji is made by cultivating koji mold on rice or wheat. The enzymes produced by the koji mold break down the starch contained in the rice into glucose (which the yeast then converts into alcohol and CO2). There are several varieties of koji spores used to produce fermented food products. The variety used in the production of Sake is a variety known in Japanese as Kikoji (yellow koji) it comes from the spores of a bacteria called Aspergillus oryzae. Kikoji is also used in the fermentation of soy sauce and miso paste. Shochu is made using Shirokoji (white koji) while Awamori is made using Kurokoji (black koji).

Acidity Level

The acidity level is a measure of the acidity and flavor of sake. The acidity level is determined by the concentration of organic acid, including succinic acid, malic acid and lactic acid. The volatile organic acid also helps to create aroma and is an important ingredient in determining the flavor of sake. High acidity levels give a dry flavor while low levels give a sweeter tasting sake.

Rice Polishing Rate

The rice polishing rate, or milling rate, is the degree to which the rice has been polished. Therefore the lower the number, the more rice that has been milled away. The rice polishing rate is calculated using the following formula. Polishing rate (%) = weight of polished rice (kg) / weight of unpolished rice (kg) x 100.

For example, a rice polishing rate of 60% indicates that the outside 40% of the grain of rice has been milled away and just the remaining 60% of the grain used in the brewing process.

Brewer’s Alcohol

Brewer’s alcohol is a tasteless, odorless alcohol fermented using the starch in rice, potato or corn which is then distilled to give high alcohol content. Adding brewer’s alcohol can make sake more fragrant and cleaner taste.

Un-pasteurized Sake/Un-pasteurized Matured Sake

During the production process Japanese Sake is generally pasteurised twice, once before it is matured and then again following the maturation period (directly before bottling). This requires heating the Sake to approx. 140-149°F (60-65°C) which neutralizes the enzyemes and stabalizes the Sake.

Un-pasteurized Sake, such as “Funaguchi”, skips this process, is bottled straight after the Sake is pressed and has the rich lively flavor unique to freshly brewed Sake. Un-pasteurized Matured Sake has fresh flavor because it matures without being pasteurized.